Unsere Kompetenzfelder

Advanced Manufacturing

Protodynamix bietet generative Fertigung im industriellen Massstab. Die werkzeuglose Produktion von Bauteilen im Selektiven Laser-Sinterverfahren (SLS) ist schnell, flexibel und kostengünstig. Die Technologie ermöglicht den Wandel vom fertigungsgerechten zum funktionsgerechten Design und dies von Stückzahl 1 bis zu mehreren 1000 Stück.

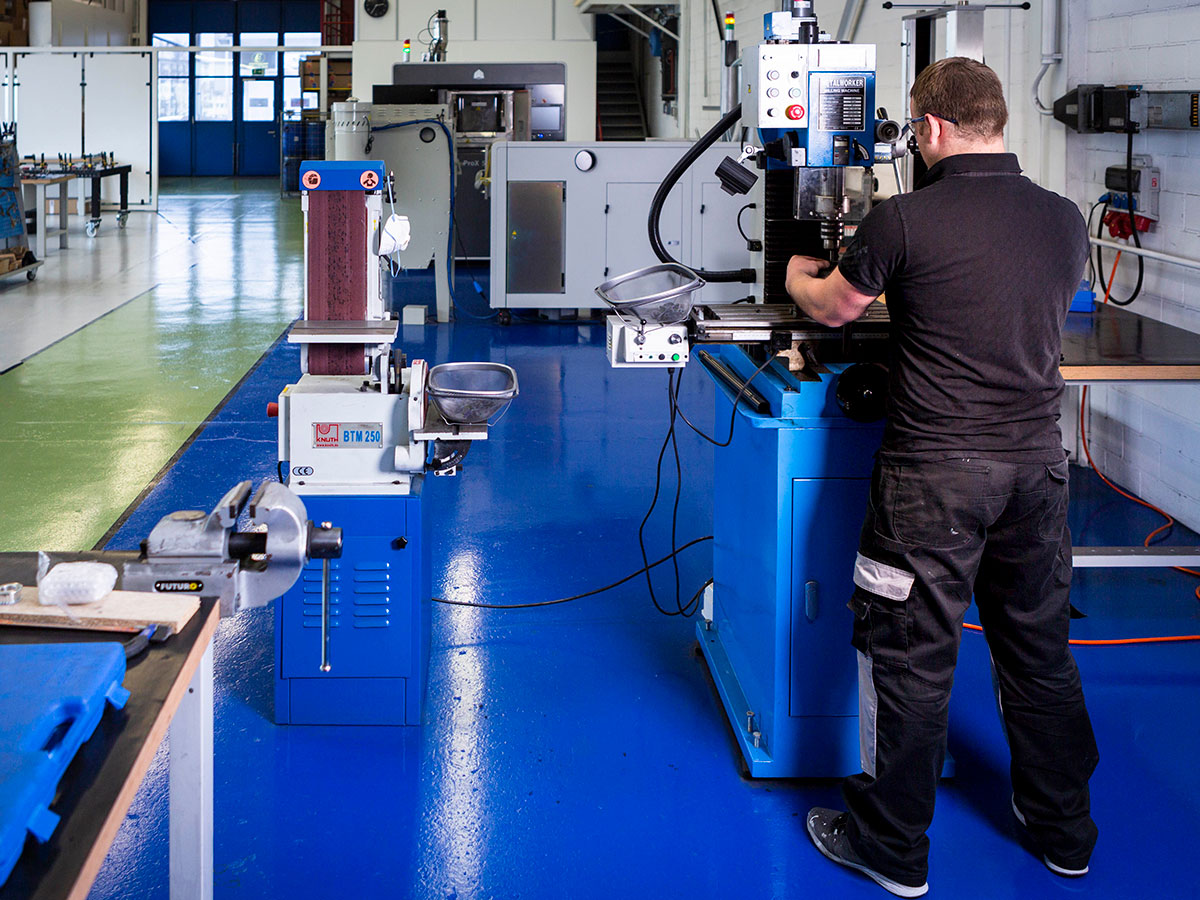

Modellbau

Mit der reinen Produktion der Bauteile ist es bei uns nicht getan. Wir bieten Ihnen sämtliche Dienstleistungen im Modellbaubereich. Von der mechanischen Bearbeitung über die Veredlung von Oberflächen bis zu kompletten Zusammenbauten sind wir Ihr kompetenter Partner.

Engineering

Unser erfahrenes Team an Ingenieuren und Spezialisten unterstützt Sie gerne auf dem Weg von der Idee zum Produkt. Mit modernsten Hilfsmitteln wie 3D Scan- und Messsystemen und CAD Software können wir Ihnen von der Flächenrückführung bis zum Messbericht alles bieten.